The automotive industry, known for its relentless quest for perfection and precision, has witnessed numerous technological advancements over the years. Among these advancements is laser cleaning, a groundbreaking method that promises to revolutionize the way automotive parts are maintained and refurbished. But what exactly is laser cleaning? How does it compare with traditional cleaning methods? And most importantly, how does it enhance the quality of automotive parts?

The Basics of Laser Cleaning

What is laser cleaning?

Laser cleaning is a non-contact and non-abrasive method that employs the power of laser beams to remove contaminants like rust, paint, oil, and other substances from various surfaces. It works by directing a high-intensity laser beam onto the surface which results in sublimation, or the process of turning a solid directly into a gas, of the contaminant.

How does it differ from traditional cleaning methods?

Traditional cleaning methods in the automotive industry, such as abrasive blasting or chemical cleaning, often involve physical contact with the part or the use of harmful chemicals. These methods, although effective, can damage the part’s integrity, endanger workers, and harm the environment. Laser cleaning machines, on the other hand, minimize these risks, making it a preferable choice for many automotive manufacturers..

Benefits of Laser Cleaning in the Automotive Sector

Before delving into the intricacies of laser cleaning, let’s briefly discuss its myriad benefits for automotive parts:

Environmentally friendly: No chemicals or abrasive materials are used, reducing environmental pollution.

Increased efficiency: Faster cleaning processes mean more parts can be cleaned in less time.

Preservation of part integrity: No physical contact means the underlying material remains undamaged.

Enhanced worker safety: Eliminates the exposure to harmful chemicals and abrasive materials.

Reduced waste and costs: Less waste generated from chemicals and used abrasive materials.

Better final product quality: Parts cleaned using lasers often have a cleaner and smoother finish.

The Science Behind Laser Cleaning

Laser cleaning, though seemingly straightforward, is underpinned by complex scientific principles. The method is incredibly effective for automotive parts because of the precision and control the lasers offer.

Ablation: The Process of Material Removal

At the heart of laser cleaning is the concept of ablation. Ablation is the process where the laser beam heats up the contaminant on the part to a point where it evaporates or is blown away. This process is localized to the contaminant itself, ensuring the underlying material remains unscathed.

Different Types of Lasers Used in Cleaning Automotive Parts

As the technology matured, various laser types were introduced, each tailored for specific cleaning tasks within the automotive industry.

Continuous Wave (CW) Lasers

Pros: Offers consistent and constant power output.

Cons: Might overheat the part if used continuously.

Pulsed Lasers

Pros: Can be controlled to release short bursts of high power, ideal for tough contaminants.

Cons: More expensive and complex machinery.

Fiber Lasers

Pros: Highly flexible and can be used for precision cleaning.

Cons: Lower power output compared to other types.

Ultraviolet (UV) Lasers

Pros: Extremely precise and can be used for micro-cleaning tasks.

Cons: Limited in terms of power.

Application Areas within the Automotive Industry

Laser cleaning has found applications in various areas of the automotive manufacturing process:

Cleaning Engine Components: Ensures efficient performance and longevity of the engine.

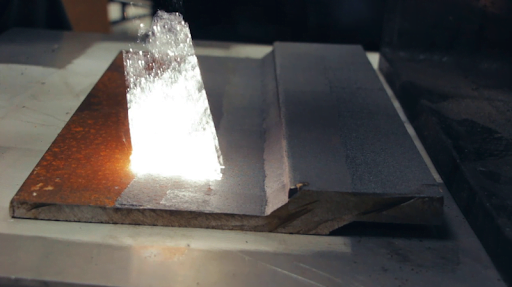

Surface Preparation for Welding: Guarantees cleaner and more effective welds.

Removal of Coatings and Contaminants: Critical for quality control and rework tasks.

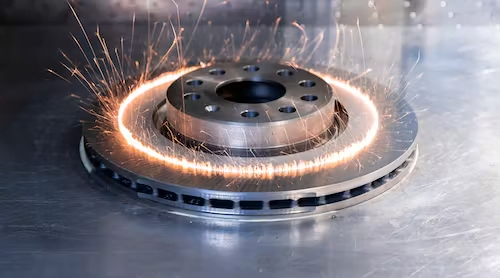

Rust and Corrosion Removal: Prolongs the life of parts by preventing premature wear.

Comparative Analysis: Laser Cleaning vs. Traditional Cleaning

When juxtaposed against traditional cleaning methods, laser cleaning clearly stands out in various aspects.

Cost-effectiveness

While the initial setup cost for laser cleaning might be high, the long-term savings in terms of reduced waste, lower maintenance, and minimized use of chemicals make it a cost-effective solution.

Time Efficiency

Laser cleaning, being a non-contact method, can be much faster than manual or chemical cleaning processes.

Safety and Environmental Impact

The non-use of chemicals and abrasive materials in laser cleaning significantly reduces the environmental footprint and enhances worker safety.

Real-world Case Studies

Companies around the globe are rapidly adopting laser cleaning. For instance:

Toyota: Used laser cleaning in their production lines to improve weld quality.

BMW: Integrated laser cleaning to refurbish old car parts, ensuring longevity and sustainability.

Challenges and Limitations

Like any technology, laser cleaning isn’t devoid of challenges. Some of these include the high initial investment, the need for skilled technicians, and potential limitations with certain contaminants or coatings.

The Future of Laser Cleaning in the Automotive Industry

As we look ahead, laser cleaning promises to become an indispensable tool in the automotive sector. With advancements in laser technology, we can anticipate more efficient, cost-effective, and environmentally-friendly solutions tailored for the industry.

Conclusion

In essence, laser cleaning in the automotive realm isn’t just about maintaining the visual appeal of parts—it’s about ensuring their functionality, longevity, and, ultimately, the safety of the vehicles we drive. With its myriad benefits, from preserving the integrity of parts to enhancing worker safety, it’s clear that the future of automotive cleaning lies in the beam of a laser.