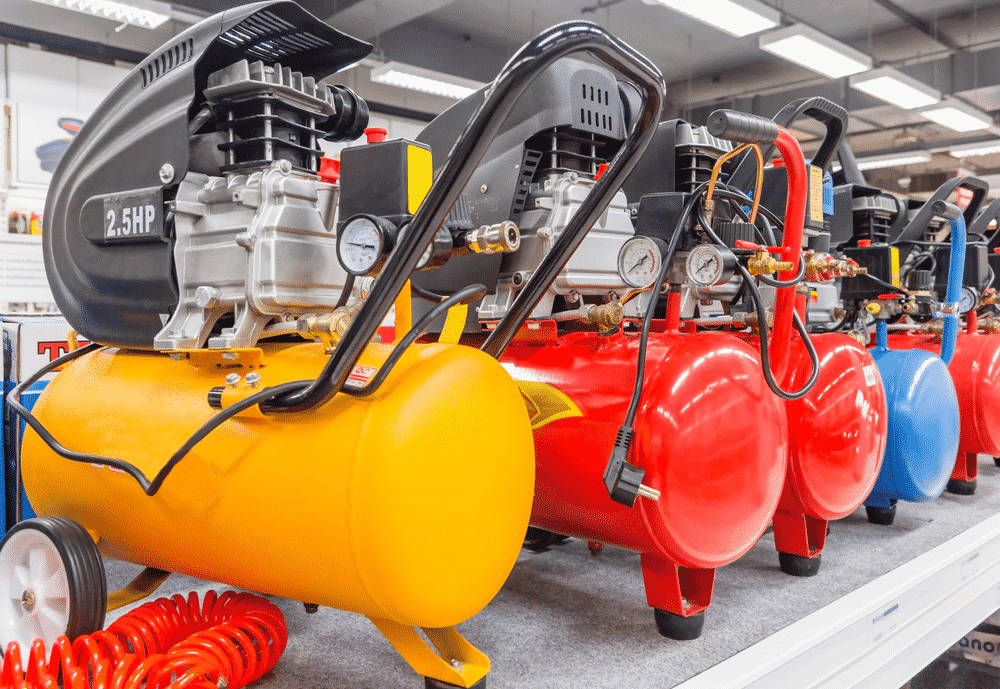

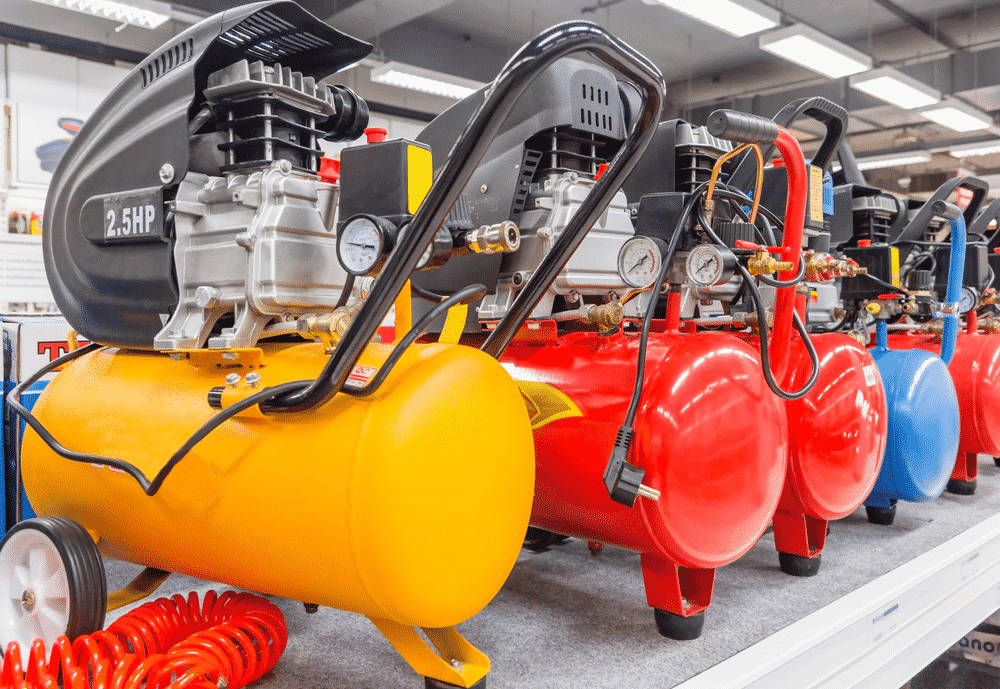

electric-powered-air-compressor

Air compressor maintenance is a vital part of owning an air compressor, as might already know.

Maintaining an air compressor improves its service life and ensures proper working. This would also help you reduce compressor running costs in the long run.

Many people, sadly, disregard these advantages. The explanation is simple: there is no regular maintenance needed for most standard air compressors. It is easy to forget in this situation that they need maintenance now and then.

Air compressor is needed on almost any conceivable pneumatic tool, this is an essential machine and a good way to ensure that it continues to function well is to do frequent cleaning. If you want the instruments to operate continuously, do not ignore the maintenance of the air compressor.

For efficient operation, longer service life, and lower operating costs of air compressors, good maintenance is very necessary. If its maintenance is ignored, inadequate maintenance leads to compressor failure and finally to malfunctions. Not only because the air compressor needs to be maintained, but also because of losses in output, decay can be expensive.

To Help Keep Your Air Compressors Clean, Follow These 11 Tips:

Follow The Instruction Manual

Read and follow the directions for usage that come with the purchase is the best way to take maintain an air compressor. Before operating an air compressor, this should be the first thing that you should read and understand. Provides ways and tricks to maintain the air compressor properly.

Drain Tanks Moisture

The air compressor tank takes moisture faster if you live in a water vapor environment. There are safety valves in most air compressors and you must ensure that these valves are released periodically. Until venting, remember to vent the air.

Tighten Fasteners

Vibrations loosen bolts, nuts, and screws while using an air compressor. Therefore, it is advisable to inspect and assemble these parts regularly to ensure that the air compressor is working properly.

Check And Change Air Filters If Needed

A large accumulation of dust and debris on the air filter of the air compressor will allow some of this waste to be absorbed. The air compressor would be impelled to function heavier than it requires. The power supply to the equipments would be reduced by this. If the build-up is already high, be sure to periodically check the air filter and replace it.

Keep The Intake Vents Cleaned

To ensure they are clean, check the compressor inlets periodically. The air compressor becomes heavier and quickly overheats if dirt and dust get inside. If the air compressor is in a dusty setting, this is extremely important.

Examine And Replace Compressor Oil

In the operation of an air compressor, tool oil plays an essential role. It acts as a lubricant and coolant which prevents the air compressor from overheating easily and prevents the wear and splitting of its parts. Follow the operating instructions on how much the compressor oil should be adjusted and what kind of oil to use.

Frequently Examine The Tool Hoses

The hoses act like the heart of an air tool, so they must be treated well. Make sure they are properly washed and no signs of cracking or corrosion are present. All other sections of the power tool will seriously affect any load on the air compressor hose and adversely affect its output.

Ensure The Tool Tank Are Well Clean

Daily fuel tank cleaning leads to better work and lasts much longer. It is necessary to clean the fuel tank, like all other tools, to ensure that the compressor gets all the power it needs.

Clean The Screw And Valve Type Heat, Exchangers

Heat exchangers are other components of air compressors that need to be filtered. A clean heat exchanger effectively lowers the air compressor’s operating temperature and helps it to operate longer. Any waste accumulating on the heat exchangers can easily contribute to the instrument overheating.

Check Your Shutdown Options

Air compressors have built-in safety shut-off options that, in the case of an emergency or serious threat, will automatically interrupt service. If it gets too hot or if the engine oil pressure drops dangerously, they normally stop the compressor.

To learn how to test this emergency stop option, read the compressor manual. Checking the safety of your tools at least once every year will benefit you greatly. Smart controls and maintenance ensure the flexibility of the system and guarantee a long service life, even in emergencies.

Establish A Schedule For The Air Compressor’s Preventive Maintenance

It is worth considering developing a preventive maintenance checklist while looking beyond cleaning a spring-loaded air compressor, which would be used to ensure the life of the air compressor during its life. There really are a lot of points to consider here.

The only way to keep the compressor going for a long time is to consider the state of the air compressor and obey the manufacturer’s instructions.

Steps To Effectively Clean Your Air Compressor

When you notice your equipment are delay in working after some time when you use the air compressor. This is a sign that you need to clean it and open it. You can do this task yourself or you can engage expertise from a registered tool cleaning company to execute it for you. If you’ve got some time, why not but in this section, 8 ways at which you can clean your air compressor easily will be review.

Read The Manual

Before touching anything on your air tool firstly read the manual. It comes with instructions on how to cleaning it. Special notices and items to be careful of will be mentioned there. It is best to check all the parts of an air compressor before opening it.

Drain Your Compressor

By opening the valve, you first remove all the air from the compressor tank. Make sure there is no air before opening, as this can lead to damages and pain. You need to clear the water after that. In the bag, do not leave anything. The slightest moisture from the exhaust must be dried out.

Scrub The Tank Clean

For this, use detergent. You can easily reach the corners if your tank is not huge. Don’t go out of place. Using clean water to wash it and let it dry.

Unclog The Vents

After months of air compressor parts, the valves are possibly full of dirt. Be sure to search for debris periodically. Impurities that obstruct the valve make the extraction of air from the air compressor difficult.

Check The Hoses

Check the hoses immediately if you hear a hiss any time you turn on the components of your air compressor. A hole is a major issue in the air compressor tubing. The hose will need to be replaced, particularly when there is difficulty to overlay the holes.

Tighten Clasps

Loose fastener hazardous. It not only absorbs your supply of air but when you use a compressor, it can blast and strike you in the face. To tighten all the loops of your air tool. This is essential, so take note of it and do it consistently.

Clean Filters

Filters should be replaced regularly to ensure their effectiveness and must be used occasionally. They filter and combine all the resulting tiny particles. Remember to carefully treat them while cleaning the filter. Brush the dirt off. For the best results, use water.

Change Lubricating Oil

Be sure to change it every day if you have an oil-lubricated compressor. If there is no more oil or if the oil is dirty, the system will not operate optimally. Using trustworthy sources and recommended oil only.

Assembly is a crucial part of cleaning. Ensure you know where each and every part of the air compressor. Also, avoid a situation where there will be a missing screw. This will affect your compressor greatly. Most people prefer to hire trained personnel to do the job for them.